An Efficient, Cost Effective Way to Treat Dangerous Hydrogen Sulfide (H2S) Gas and Neutralize Its Odor

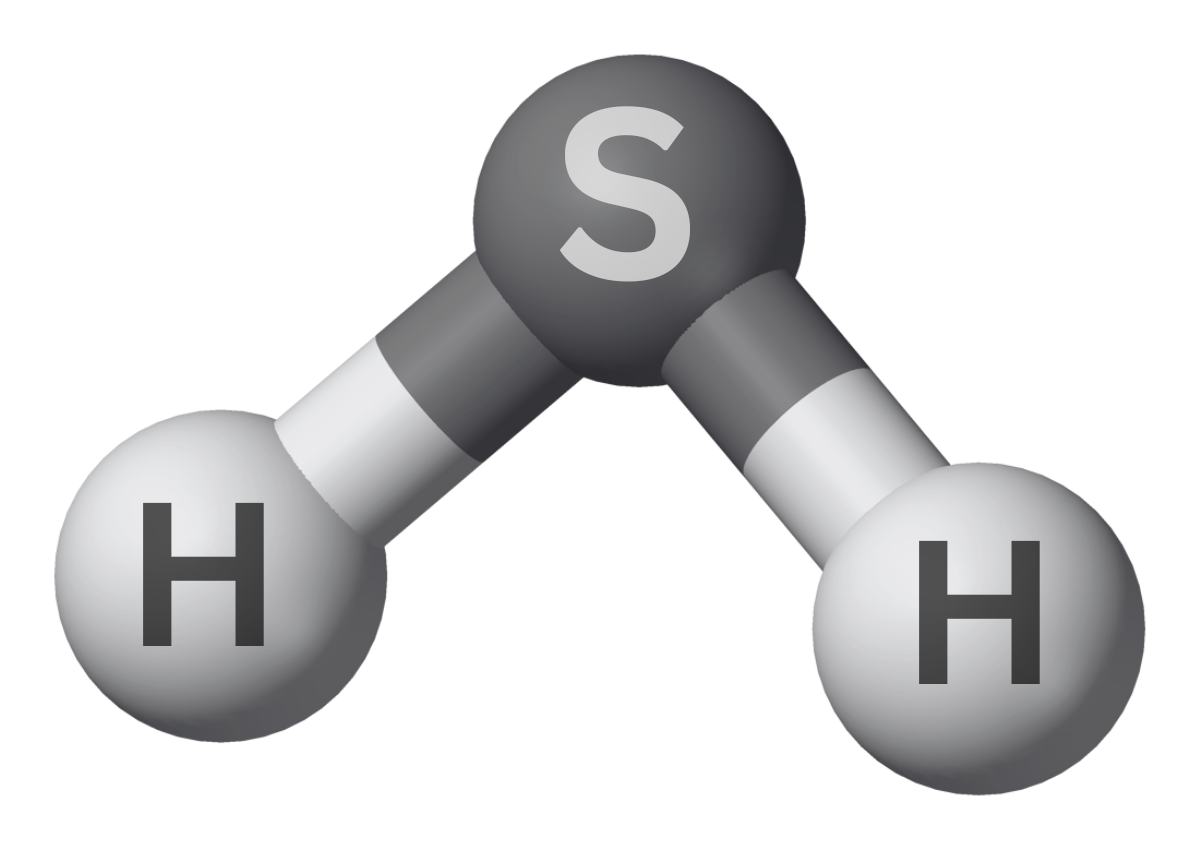

What is Hydrogen Sulfide (H2S)?

Hydrogen sulfide (H2S) is a colorless gas that is heavier than air with the distinct odor of rotten eggs. It is produced during the breakdown of organic matter by bacteria in anaerobic conditions. H2S is commonly found in wastewater treatment plants, paper mills, refineries, textile plants, landfills, and almost every other industrial process in the world.

H2S is highly corrosive and can damage infrastructure such as pipes, pumps, and similar equipment. H2S is also toxic, posing risks to human health and safety.

H2S Smells Awful & Causes Pollution

Hydrogen sulfide (H2S) is the most common odor-causing chemical in industrial and municipal wastewater environments. It is often referred to as the “rotten egg” smell that inundates communities. H2S also contributes to pollution through its oxidation process, which forms sulfur dioxide (SO2), a major component of acid rain.

Ultra-S3® removes the stink and protects the environment.

Learn MoreH2S is Highly Toxic & Can be Deadly

Even at lower concentrations, hydrogen sulfide (H2S) gas can cause shock, convulsions, inability to breathe, extremely rapid unconsciousness, coma, and death with as little as a single breath. H2S is also flammable and explosive. Yet, workers in wastewater treatment plants and other industrial settings are exposed to hydrogen sulfide every day.

Ultra-S3® eliminates H2S gas to prevent illness and death.

Learn MoreH2S is Corrosive & Destructive

When exposed to hydrogen sulfide (H2S) gas, metals such as iron and steel undergo significant sulfide corrosion, leading to weakened structures and pipeline failures. H2S reacts with concrete similarly, causing cracking, deterioration, and oftentimes collapse. Its corrosive nature poses significant risks to the integrity and lifespan of infrastructure systems.

Ultra-S3® eliminates H2S to increase infrastructure lifespan.

Learn MoreThe Sustainable Solution

Ultra-S3® is an effective oxidizing system used successfully in the United States and abroad for over a decade. It has been used in landfills, wastewater treatment facilities, air scrubbers, wastewater retention ponds, food processing plants, chemical plants, paper mills, sewage lines, and more.

Ultra-S3® is cost-effective and will treat many recalcitrant chemicals such as hydrogen sulfide (H2S), benzene, methyl tert-butyl ether (MTBE), toluene, trichloroethylene, and many others.

How Does Ultra-S3® Work?

- An oxidant, generally hydrogen peroxide (H2O2), and Ultra-S3® are injected separately into the waste stream or over the target area.

- When combined with an oxidant, Ultra-S3® produces hydroxyl radicals that break down difficult chemical bonds to remediate organic compounds to non-detectable levels.

Why Choose Ultra-S3®?

- Efficient – Rapid reaction that results in oxidation of

contaminants to primarily CO2 and H2O - Easy – Requires minimal capital infrastructure investment

- Cost-effective – Compares very favorably to other

competitive treatment solutions on the market

- Safe – Classified as non-hazardous under the Toxic Substance Control Act of 1976 (TSCA)

- ROI – Prolongs infrastructure life

- Targeted – Targets problem compounds without destroying environmentally beneficial microbes

Proven Applications

Wastewater Treatment Plants

Lift Stations

Lagoon Remediation

Repurposed Scrubbers

Industrial Processes

Pond Remediation

One Northern California wastewater treatment plant used Ultra-S3® to eliminate a serious hydrogen sulfide (H2S) problem. Although H2S is pungent in low concentrations, it paralyzes the olfactory nerve at levels above 100 ppm to render workers oblivious to the danger.

The wastewater in this plant had hydrogen sulfide levels of 7–10 ppm, which produced concentrations in the sewer air averaging 102 ppm and peaking at 250 ppm. The objective of the Ultra-S3® treatment was to reduce the H2S concentration in the air to an acceptable level (less than 10 ppm).

The end result? The Ultra-S3® process worked rapidly with most of the treatment being accomplished within three minutes of contact time. The treatment reduced the hydrogen sulfide concentration in the air to less than 1 ppm, a reduction of approximately 1200 pounds of hydrogen sulfide.